Block Error Rate and Burning Quality

When I am archiving my discs to M-Discs I want to get to make sure I get the best quality results. This then means that you need to measure the quality of the various drives. The problem is actually more complicated than it appears as although CD's, DVD's and Blu Rays all look very similar with 12cm polycarbonate discs there are big differences in what the error rates of each disc mean.

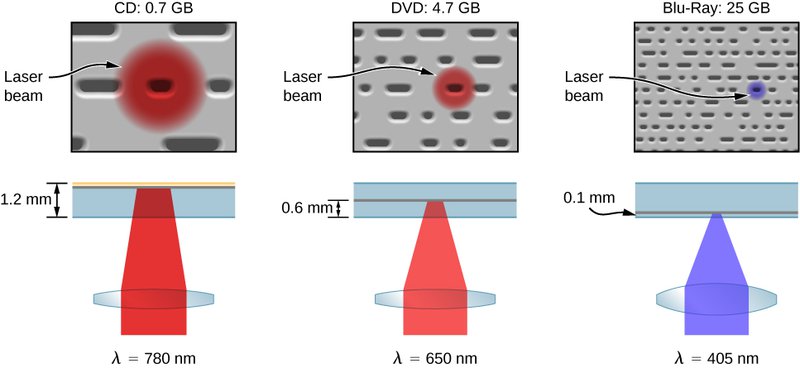

The difference comes in that there is a big difference in the quality of the raw drive to the quality of the information stored on it. The raw data is stored in pits - for a diagramatic view see this:

The raw data is corrected by algorithims that vary across the technologies to proved final results. When you verify a disc you are verifying that the final information after all the error correction is the same. However by looking at raw quality of the information you can get a metric of how good the quality of the disc is and if it is deteriorating long before information is actually lost.

The collecting of information for CD's is widespread and many burners support it. At the time of writing I have been unable to find a commercial disc and software to measure the raw error rate of Blu Ray drives. So I am going to test on CD's and apply the lessons to the Blu Ray drives.

CD Technology

As CD Technology is the earliest it is also the simplest to understand. In order to understand the block error rate you need to understand how raw information on the disc is converted to sector information. There are a number of layers of correction information and only if the errors are sufficiently large will the sector information actually be an error.

The first level of error correction is that 8 bit bytes are converted to a 14 bit pattern with a 3 bit seperator (8 into 14 modulation (EFM)). The reason this is done is both to have additional error correction but also to reduce the highest frequencies used. So single bits are never used. This is the first error correction level. There is then a further level correction level. At the back of a review there is a very good table showing how the information from sectors is laid out on the disc.

"

WHAT ARE ERRORS?

Block errors on a disc are not a physical thing. They are a manifestation of how a disc interacts with a player. So different players can produce different error-rates from the same disc. Although there are rigid specifications that define what a CD should be, there are no such specifications for players. Therfore, to ensure wide compatibility, discs should have low errors. Additionally, a disc that is unreadable on one player, may seem to perform well on another.

The CIRC error correction used in CD players uses two stages of error correction called C1 and C2, with de-interleaving of the data between the stages. The error correction chip can correct two bad symbols per block in the first stage and up to four bad symbols in the second stage.

BLER

BLER, or Block Error Rate, is the number of data blocks per second that contain detectable errors at the input of the C1 decoder. The “Red Book” specification allows BLER up to 220 per second averaged over 10 seconds. These days, with high speed readers commonplace, the generally accepted maximum is 50.

E11, E21, E31

An E11 error means one bad symbol was corrected at the C1 stage. An E21 error means two bad symbols corrected at the C1 stage. E31 means three or more bad symbols at the C1 stage, and is uncorrectable at C1 and so is passed on to the C2 stage.

Because the data is de-interleaved between the stages, each of the bad symbols is now in separate blocks, and so they can be handled by the C2 stage. As a result of the interleaving, one uncorrectable symbol at C1 can become up to 28 bad symbols at C2, which is why E12 is often much higher than E31.

E12, E22, E32

An E12 error means that one bad symbol was corrected at the C2 stage. E22 is two bad symbols, and E32 is three or more bad symbols at C2 and therefore cannot be corrected. It is theoretically possible for C2 to correct four bad symbols, but not all players can do so. To allow for high compatibility, we consider E32 to be uncorrectable, even though some drives may be able to correct it" [1] deanwitty

CD Block Error Rate

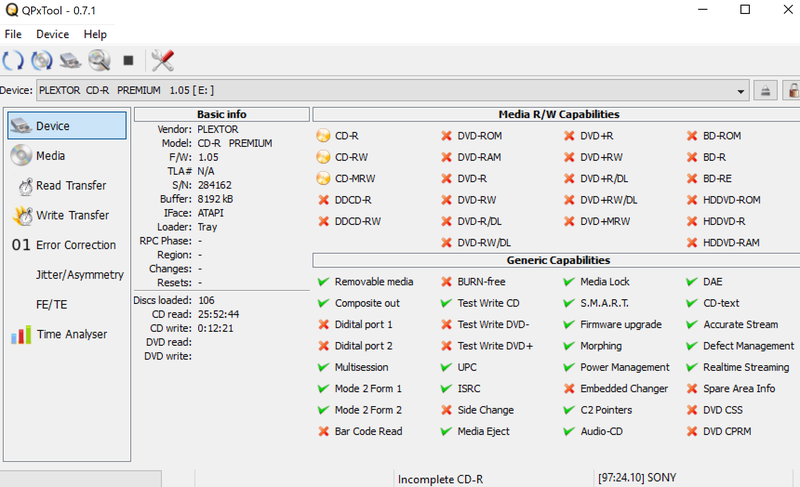

A number of tools were tested eg OptiDrive, Nero Speed Test but the one that gave the best information was QPXTools

The above image shows the information it gives on each drive. It also has a nice command line tool which gives full information.

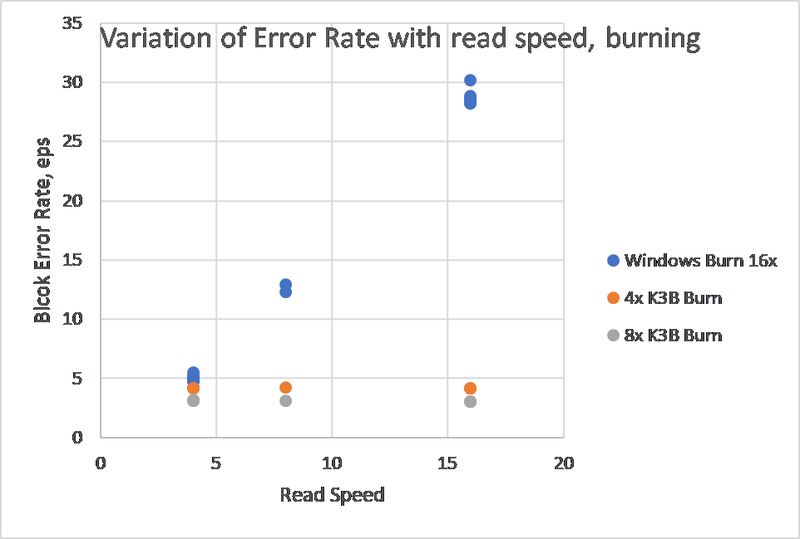

Using a number of discs

This shows that the biggest variation is via burning program. The results are a bit unexpected as the variation by the K3B burning program seems to be different to that recorded by the Windows burning program. All the tests and burns were carried out on a Plextor Premium CD drive with 1.07 Firmware (excepting the Windows burn which was done with 1.05 firmware).

Further testing is going to be required. It also points to trying to find a Blu Ray testing regime in order to get good data.

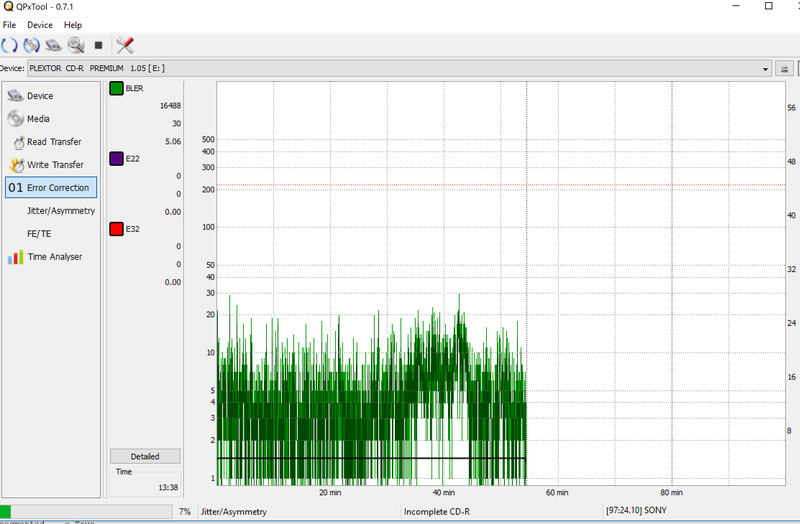

The Gui can show variation of the read quality across the disc.

Blu Ray Testing

As mentioned above QPXTools will not test on any of the drives I currently have.

Reading a CDRinfo [2] test of different blu ray media I was struck how important it was to not put your finger prints on your discs before recording (slightly more tolerant when reading). Generally data signals recorded over fingerprints contain much more errors than ROM data signals read through fingerprints.

This is the reason that fingerprint-resistance is viewed as more crucial property in BD-RE or BD-R, compared to BD-ROM."

The implication of this that ideally you need to have a clean air supply and a hands free environment.

References

[1]: ‘E11, E21 Etc. Simplified’. Club Myce - Knowledge is Power. Accessed 7 June 2018. https://club.myce.com/t/e11-e21-etc-simplified/303609.

[2]: ‘Blu-Ray Writing Quality Tests - Printer Friendly Version’. Accessed 6 June 2018. http://www.cdrinfo.com/Sections/Reviews/Print.aspx?ArticleId=20888.